Landers, Frary & Clark

Colt was not the only company in Connecticut to produce war goods during World War I, one of the many other companies was Landers, Frary & Clark which existed in New Britain. The company was incorporated in 1862 by George M. Landers with the purchase of the Meriden business Frary & Clark. In 1866 the company began to manufacture cutlery and over time the business concentrated in the production of kitchen supplies. For example, they produced food scales, coffee grinders, cake mixers, bread makers, coffee pots, percolators, and a number of different knives. Starting in the 20th century, Landers, Frary & Clark began making electronic home appliances such as toasters, irons, blenders, etc. When the First World War began Landers, Frary & Clark did not have the advantage that Colt had as Colt was already manufacturing products that could be used for the war such as guns. Landers, Frary & Clark had to transition to war production. The company did this by reworking the products they were already manufacturing. Some products were easy to transition to, such as mess kits, but others took more time, such as Calvary swords. Landers, Frary & Clark decided to change their cutlery division to war production, making a multitude of different knives for the war. They made Calvary swords, trench knives, bayonets, army knives, amputating knives, saddler’s knives, surgeon’s lancet and operating knives, and parachute knives, but cutlery was not the only thing the company produced. Making a diverse set of war products, such as gas mask parts, canteens, mess kits, and canteen cups, was a good way for Landers, Frary & Clark to attain war orders.

New Britain Industrial Museum.

Welcome Home Hardware Center of the World.

During the First World War, the United States government gave Landers, Frary & Clark a war order for the Model 1913 Patton Cavalry Saber. The saber was designed in 1913 by George S. Patton who would become one of the most famous generals in World War II. The 1913 design replaced the older 1906 Cavalry saber. Unlike the 1906 design, the 1913 had a straight blade instead of a curved blade and was equipped by all United States Cavalry forces. Landers, Frary & Clark produced almost all of the 1913 sabers. The Patton saber was the last Cavalry saber to be issued to the United States Cavalry because by World War I cavalry was no longer useful in combat. A soldier mounted on a horse was too large of a target for rifles, machine guns, and artillery. This meant that cavalry soldiers in the Great War would ride their horses up to the front, dismount, and fight as normal soldiers, like a dragoon. While cavalry combat saw its final end in World War I, the production of the sabers for the United States brought Landers, Frary & Clark a considerable amount of money through war orders. Much like Colt, Landers, Frary & Clark saw tremendous prosperity during World War I. The increase of manufacturing from items such as cavalry sabers allowed Landers, Frary & Clark to expand their factory and workforce.

New Britain Industrial Museum.

Welcome Home Hardware Center of the World.

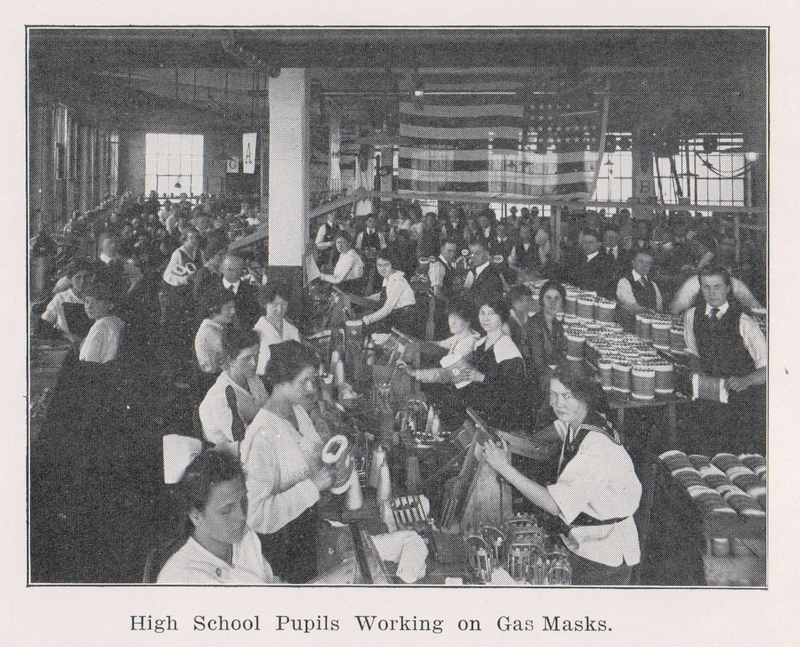

The First World War was the first time chemical warfare took place on an industrial scale. Both the Entente and Central powers used gases such as mustard and chlorine. The Entente refers to the alliance between France, Great Britain, Italy, and the United States among others; the Central Powers refer to Germany, Austria-Hungary, Ottomans, and Bulgarians. All of these nations needed to protect their soldiers from chemical attacks on the front line. With millions of soldiers facing this threat on a daily basis there was a high demand for gas masks. The masks were complex devices which were relatively new to manufacturers. This meant that companies such as Landers, Frary & Clark produced only part of a gas mask. It also meant that there were many things that could go wrong with the masks, and during the war a deficiency in the gas masks was discovered that meant the masks did not work against mustard gas. When the United States government realized this they were frantic to replace all existing gas masks. They needed 300,000 gas masks from New Britain in only 30 days. The entire city came together and the many different companies in town that produced gas masks, including Landers, Frary & Clark, brought in school children and women to make these masks. Working day and night, the city of New Britain was able to produce these gas masks in time for the United States government. This remained a point of pride for the city for some time.

New Britain Industrial Museum.

Welcome Home Hardware Center of the World.

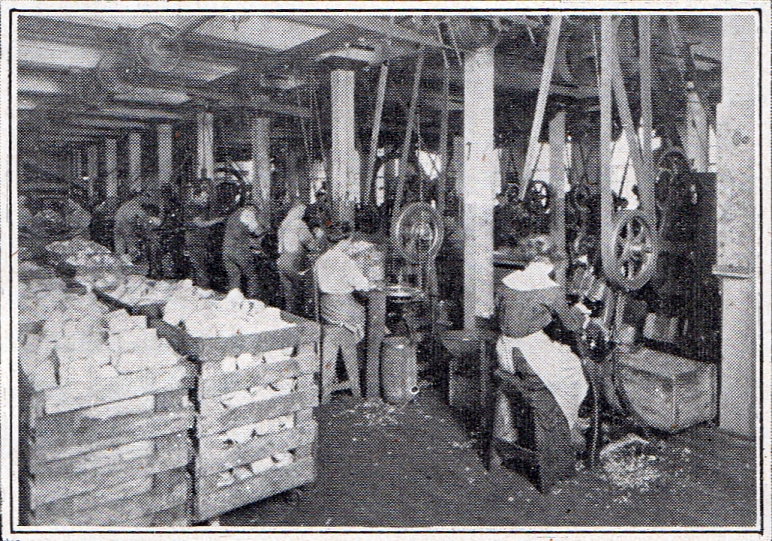

One of the most ordered products that Landers, Frary & Clark made was the mark 1 trench dagger. It has an easily recognizable design; it had a triangular blade and a brass knuckle handle. This allowed for soldiers fighting in close combat to either stab or punch their opponent. This design of a triangle blade makes it almost impossible to stitch a wound closed, which made it a controversial weapon. A second design was produced later in the war with a normal flat blade with a “skull crusher” pommel. The pommel was a knob at the end of the handle used to bash an opponent. With this pommel on the trench knife, a user could stab, punch, or bash someone with three different sides of the knife. This might seem excessive but close-quarters combat was not uncommon in World War I when soldiers would jump into the enemy trenches. It proved to be a popular design and it was used in World War II as well. Landers, Frary & Clark was given war orders to produce 5 million trench knives, which included the mark 1 trench dagger and other knives. At its peak, Landers, Frary & Clark was making 30,000 trench knives a day. Another highly produced item that the company made was canteens, of which they made 3 million. To reach this number they needed to expand their factories and workforce.

New Britain Industrial Museum.

Welcome Home Hardwar Center of the World.

During the final year of the First World War, Landers, Frary & Clark needed to expand to meet their production needs. The United States government had given the company a war order for 500,000 bayonets. Landers, Frary & Clark were unable to meet this large of an order when they were already producing cavalry sabers, trench knives, canteens, and many other items. They needed to expand their factories and workforce to complete the order. The business purchased the National Spring Bed Company in Meriden and with this new factory they would be able to produce the 500,000 bayonets. Landers, Frary & Clark quickly went to work equipping the new factory to produce the bayonets. Although the war ended before the company was able to complete the order this new facility allowed Landers, Frary & Clark to expand their workforce and production for a larger capacity during peace time. While bayonets and sabers might not have been useful during peace time, the company quickly switched back to kitchen appliances and cutlery after the war. Many of the items they made during the war could also be used during peace time, such as a mess kit, canteen, or surgical knives. Landers, Frary & Clark would emerge from the war with an expanded production, product line, and workforce; including a large number of women.

New Britain Industrial Museum

Welcome Home Hardwar Center of the World.